High-End Custom Caps OEM/ODM Manufacturer in Guangzhou

One-stop support from design assistance and rapid sampling to scalable mass production--built for brands that need reliable quality, speed, and consistency.

In-house embroidery and accessories integration for complete manufacturing solutions.

*Fast lead-time depends on style, materials availability, and artwork approval.

Custom Cap Styles for Every Market

Choose a category to explore materials, fits, closures, and branding options.

Baseball Caps

Classic 6-panel construction

Snapback Caps

Adjustable flat brim style

Trucker Caps

Mesh back ventilation

Golf Caps

Performance materials

Beach Hats

Open crown design

Bucket Hats

360° sun protection

Dad Hats

Relaxed curved brim

5-Panel Caps

Minimalist construction

Straw Hats

Natural materials

Customize Every Detail--Built to Match Your Brand

From structure and fit to fabrics and finishing, we support full customization for both mainstream and niche programs.

Style & Structure

- • Panel construction options

- • Crown height variations

- • Brim shape customization

- • Fit adjustments

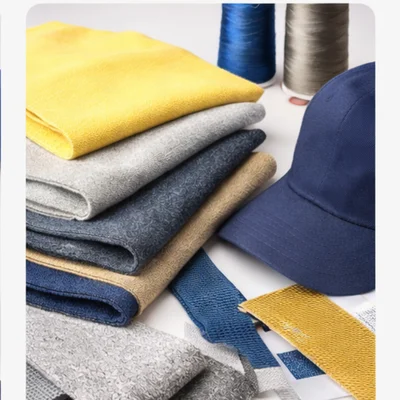

Materials

- • Cotton & polyester blends

- • Nylon & mesh options

- • Wool blends

- • Specialty fabrics

Colors

- • Pantone-matched options

- • Custom color development

- • Multi-color combinations

- • Color consistency control

Closures

- • Snapback adjusters

- • Buckle strap systems

- • Velcro closures

- • Fitted & elastic options

Branding Placement

- • Front, side & back panels

- • Brim positioning

- • Underbrim branding

- • Inside taping options

Finishing & Packaging

- • Custom labels & hangtags

- • Polybag packaging

- • Export-standard packing

- • Branded packaging options

Premium Decoration Techniques

Master the most popular decoration methods with our advanced equipment and skilled craftsmen for exceptional brand presentation.

Flat Embroidery

Clean, professional finish with precise stitching. Perfect for logos and text with crisp definition.

3D Embroidery

Dimensional impact with raised foam backing. Creates premium texture and visual depth.

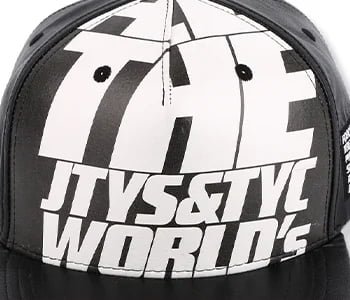

Silk Screen Printing

High-volume production with vibrant colors and smooth finish. Cost-effective for large orders.

Heat Transfer

Vibrant colors and smooth finish. Ideal for complex designs and photographic images.

Heat Press

Durable vinyl application with excellent adhesion. Perfect for bold graphics and numbers.

Woven Label

Premium textile labels with intricate weaving patterns. Professional finishing for brand identity and durability.

Why Choose EASTLUCKY

15 Years of Excellence

Proven track record serving 100+ international brands with consistent quality and reliable delivery

Complete Integration

One-stop solution from design to delivery with in-house production chain and quality control

Flexible & Fast

MOQ from 50 pieces with 7-day fast delivery and 24/7 responsive support

Certified Quality

BSCI, ISO, SGS certified with strict 12-step production and 11-step sales procedures

Our Commitment

"Building efficient, reliable, and scalable supply chains for global success"

Six-Step Production Process

From cutting to packaging, our standardized workflow ensures consistent quality and efficient delivery

Cutting

Precision fabric cutting using advanced pattern templates, ensuring accurate dimensions and material efficiency for each cap component.

Embroidery

High-precision embroidery using 5 Tajima machines, creating vibrant logos and detailed patterns with consistent thread tension and color accuracy.

Sewing

Expert seamstresses assemble cap components with reinforced stitching, ensuring durability and perfect fit for all cap styles.

Shaping

Professional cap shaping using 2 Dongil pressing machines from South Korea, achieving perfect crown structure and brim curvature.

Quality Control

Comprehensive 12-step quality inspection covering dimensions, stitching, embroidery alignment, and finishing to meet international standards.

Packaging

Professional packaging with protective materials, proper labeling, and export-standard cartons ensuring safe delivery worldwide.

Production Capabilities

From Inquiry to Delivery: Your Journey with EASTLUCKY

Our standardized 12-step production process and 11-step sales procedure ensure transparent progress control and consistent results from concept to completion.

1. Initial Inquiry

Share your requirements, design concepts, and quantity needs with our responsive team

2. Quote & Planning

Receive detailed pricing, timeline, and technical specifications within 24 hours

3. Sample Development

Expert pattern makers create prototypes with our 50 caps/day sampling capacity

4. Mass Production

In-house production with quality control and real-time progress updates

12-Step Production Process

Standardized workflow covering cutting, sewing, embroidery, pressing, inspection, and packaging with strict quality checkpoints.

11-Step Sales Procedure

Comprehensive service protocol ensuring smooth coordination, transparent communication, and on-time delivery.

Fast Track Options

Express delivery in as fast as 7 days for urgent orders, with minimum quantity starting from just 50 pieces.

Process Advantages

"From inquiry to delivery, we make customization simple, fast, and dependable for brands worldwide."

Trusted by 100+ International Brands

See why leading brands choose EASTLUCKY for their custom cap manufacturing needs

Customer Satisfaction Metrics

"Working with EASTLUCKY feels like having an extension of our own team. Their attention to detail and commitment to deadlines is unmatched in the industry."

- David Park, Global Sourcing Manager, Premium Sports Brands

Ready to Build Your Next Cap Program?

Send your logo and target quantity--our team will recommend materials, branding techniques, and a production plan that fits your timeline and budget.